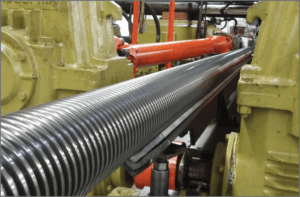

Specializing in, but not limited to, Acme and trapezoidal thread rolling, our formed threads are second to none. Meticulous inspection of our dies and innovative QC tooling assure geometric consistency across the length of your lead screw equal to or greater than what is expected.

CAPABILITIES

We offer national course, fine, and Acme threads as aggressive as 1.5 pitch, in addition to metric and trapezoidal threads. These threads may be in right-hand configuration or left. Additionally, our CNC department will machine bar ends to customer specifications as required. We make an assortment of round and cylindrical nuts to mate with our threaded rod, as well as special screws and nuts to meet our customer needs.

PART DIMENSIONS

We are able to roll threaded rods ranging in size diametrically from ¼ through 15 inches. There is no limit on how long the threaded rods may be, although our most common lengths tend to be between 12 and 24 feet in OAL. The largest nut made for a specialty order was to mate with a 10” screw, which was also made here at Keystone Threaded Products.

TIGHTEST TOLERANCES

In terms of lead accuracy, the standard for Acme-2C is within 0.7 MIL per inch (0.0007/1). This tolerance is eased somewhat for the Acme 2-G, which is maintained within 1 MIL per inch (0.001/1). As for pitch diameter tolerance, we will often produce 3A grade threads, which often require as low as 3 MIL total allowance.

Volume

10 Million or more per year in Sales

Industry For Use

In-Process Testing/Inspection Performed

Standards Met

ISO 9001 ASTM; ASME; AMS; As required by customer

Keyalloy is the trademarked name that Keystone uses for our alloy heat treated roll threaded bars. Keyalloy is a 4140 alloy steel heat treated to the requirements of ASTM A193 / ASME SA 193 Grade B7, latest revision.

Hot dip galvanized bars are only available in products up to three feet in length. We do not stock any bars that are hot dip galvanized; therefore, a minimum plating charge would incur on all special orders.

A machined chamfer is a mechanically created chamfer produced by means of a secondary operation. A 30° axial (60° included angle) measured below the minor diameter of the bar is produced. A rolled chamfer is created during the process of roll threading bars. It results in a good starting thread, but creates no measurable angle.

A machined chamfer is a mechanically created chamfer produced by means of a secondary operation. A 30° axial (60° included angle) measured below the minor diameter of the bar is produced. A rolled chamfer is created during the process of roll threading bars. It results in a good starting thread, but creates no measurable angle.